Analytical Chemistry & Physical Testing

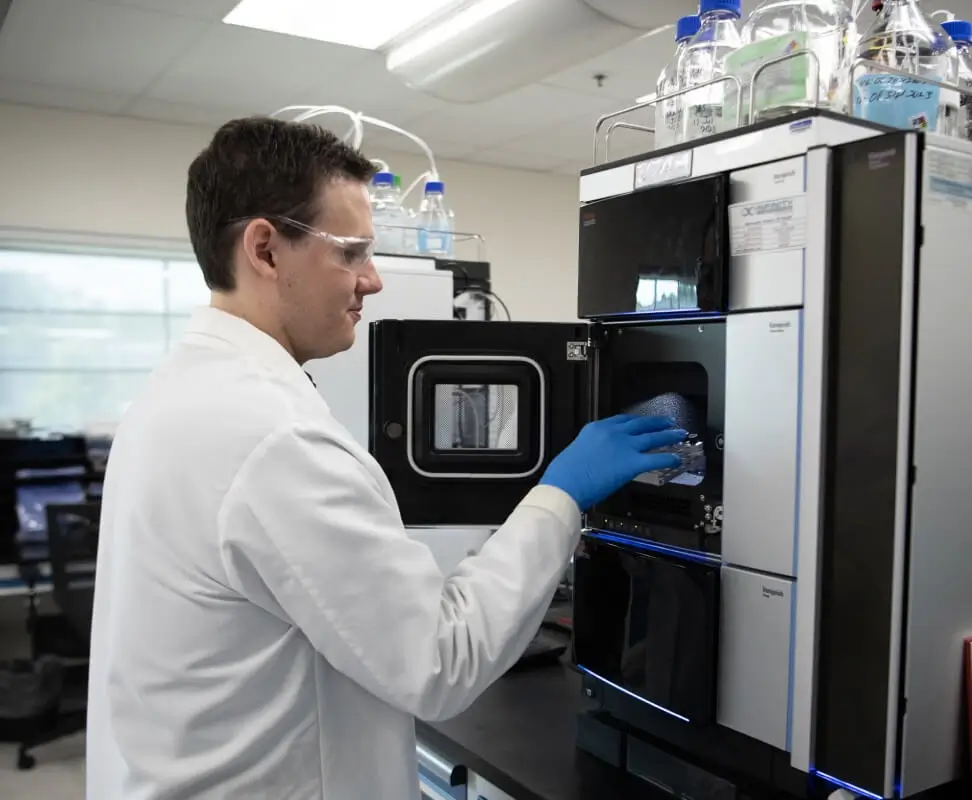

Infinity Laboratories’ team of experts and network of state-of-the-art testing facilities provides comprehensive method development, validation, and analytical testing services to pharmaceutical and medical device organizations nationwide. We offer the expertise to support the entire product lifecycle from early-phase development to commercial production, including raw materials, API, and finished therapeutic products.

Infinity Laboratories’ team of experts and network of state-of-the-art testing facilities provides comprehensive method development, validation, and analytical testing services to pharmaceutical and medical device organizations nationwide. We offer the expertise to support the entire product lifecycle from early-phase development to commercial production, including raw materials, API, and finished therapeutic products.

Timely Turnaround & Dependable Results

We have the size and capacity to provide high-quality, reliable data under demanding timelines. Our highly experienced professionals utilize state-of-the-art instrumentation to support product understanding throughout the entire product lifecycle. Operating under the governance of our internal quality assurance group, we assure strict compliance with GMP and other regulatory standards.

Analytical Method Development & Validation

Vigorous methods are required for comprehensive product understanding, ultimately ensuring product quality and patient safety. Infinity Laboratories supports analytical method development for a wide range of analytical techniques and products, and we provide method validation services for methods developed by our team, your in-house team, or other partners.

Chemical & Physical Testing Services

Infinity Laboratories operates a network of nationwide labs, providing the flexibility and service of a local lab with the resources and expertise of a national organization. Guided by the standards of the world’s leading regulatory agencies, we deliver on-time results with high data integrity.

Antimicrobial Agents

Antimicrobial Agents

Standard: USP <341>

This assay demonstrates that the declared antimicrobial preservation agent present within a multiple-dose injectable does not exceed the labeled amount by more than 20%.

Appearance Evaluation

Appearance Evaluation

Standard: Visual

Evaluating a drug product’s physical appearance can be subjective; however, it is a vital procedure for product quality and understanding. As an example, color can serve as a gross purity marker and a way to detect contaminants and degradents introduced during synthesis or storage.

Chromatography

Chromatography

Standard: USP <621>

The types of chromatography useful in qualitative and quantitative analysis employed in USP procedures include column, gas, paper, thin-layer (including high-performance thin-layer chromatography), and pressurized liquid chromatography (commonly called high-pressure or high-performance liquid chromatography).

Container Closure Integrity Testing

Container Closure Integrity Testing

Standard: USP <1207>

This standard addresses the microbiological integrity of sterile product packaging, including the container, closure system, and sterile barrier packaging of medical devices, including in vitro diagnostic products.

Dosage Uniformity

Dosage Uniformity

Standard: USP <905>

This standard ensures the consistency of drug substance within a batch aligns with the narrow range around the label claim.

Elemental Impurities

Elemental Impurities

Standard: USP <232> and USP <233>

Elemental impurities are defined as residual catalysts or environmental contaminants that may be present in drug substances, excipients, or drug products. Whether these impurities occur naturally, are added intentionally, or are introduced inadvertently, testing is required for assurance of the specified levels.

Material Identification (IR)

Material Identification (IR)

Standard: USP <197>

The IR absorption spectrum of a substance provides some of the most conclusive evidence of the identity of the substance. This standard, and corresponding methods, are integral for monograph testing and product quality.

Melting Range

Melting Range

Standard: USP <741>

Melting point (MP) determination is a raw material and drug product characterization assay. Most substances exhibit a melting transition, spanning the temperatures at which the first noticeable change of phase is detected to when no solid phase is detected. MP methods must be carefully selected to generate certifiable results for quality control and quality assurance.

Particulate Matter in Injectables

Particulate Matter in Injectables

Standard: USP <788>

Particulate matter in injections (or parenteral infusions) assays determines the presence of mobile undissolved particles, other than gas bubbles, unintentionally present in the solutions.

pH

pH

Standard: USP <791>

pH measurements are characterization assays to determine or confirm pH levels for drug compatibility, quality control, and/or shelf-life stability concerns. For compendial assays, pH is defined as the value measured by a properly calibrated, potentiometric sensor and measuring system.

Residual Solvents

Residual Solvents

Standard: USP <467>

Methods to determine that residual solvents used or produced in the manufacture of drug substances or excipients or in the preparation of drug products do not exceed specified ranges. Residual solvents are organic volatile chemicals with no therapeutic benefit, and must be removed to the extent possible for quality-based requirements.

Specific & Optical Rotation

Specific & Optical Rotation

Standard: USP <781>

Many pharmaceutical substances, like some crystals and many pharmaceutical liquids or solutions of solids, are optically active. For appropriate substances, optical rotation assays are highly informative characterization assays and the best means for distinguishing optically active isomers from each other, making this test an essential part of identity and purity.

Water Content

Water Content

Standard: USP <921>

Guided by USP 921, Karl-Fischer titration is used to determine water content in a variety of substances. Many life science products either are hydrates or contain water, and the determination of the water content is important in demonstrating compliance.